Malabou’s metrology verification is led by our CMM. We utilise the advanced PC-DMISR software to directly import the CAD model and create customised inspection reports.

METROLOGY

Our team of Metallurgists and Engineers will ensure you have complete confidence the product supplied.

Our inspection and testing laboratories provide Metallographic, Mechanical, Dimensional and Chemical testing.

We will tailor an Inspection and testing regime to meet your requirements. Our Quality Plans range from routine testing to fully documented verification and traceability.

Co-Ordinate Measuring Machine CMM

Co-Ordinate Measuring Machine CMM

Radiography

Radiography

Magnetic Particle Inspection

Magnetic Particle Inspection

Die Penetrant Inspection

Die Penetrant Inspection

Spectrographic Chemical Analysis

Spectrographic Chemical Analysis

Tensile Testing

Tensile Testing

Compression Testing

Compression Testing

Bend Testing

Bend Testing

Hardness Testing

Hardness Testing

Metallography

Metallography

CMM (Coordinate Measuring Machine) Capability

Chemical Analysis:

Chemical Analysis using spectrometer capable of 27 elements allowing testing of Ferrous, Copper base and Aluminium Alloys. Supported by Carbon and Sulphur apparatus for Cast Irons. Full range of ASTM Certified Reference Materials (CRMs) for calibration of instrument.

Mechanical Testing

Computerised Universal Testing Machine

To perform Tensile Test, Compression & Bend Test as per ASTM E8/E8M

To perform Tensile Test, Compression & Bend Test as per ASTM E8/E8M

To perform Tensile Test, Compression & Bend Test as per ASTM E8/E8M

To perform Tensile Test, Compression & Bend Test as per ASTM E8/E8M

Brinell Hardness tester

Brinell hardness on ferrous & Non Ferrous Samples as per ASTM E10

Brinell hardness on ferrous & Non Ferrous Samples as per ASTM E10

Testing Range: Upto 650 BHN

Testing Range: Upto 650 BHN

Ball Size: 5mm & 10mm

Ball Size: 5mm & 10mm

Load Range: 750, 1000, 3000 kg

Load Range: 750, 1000, 3000 kg

Rockwell Hardness Testing machine

Rockwell Hardness as per ASTM E18

Rockwell Hardness as per ASTM E18

Scales: A, B, C, Superficial N & T

Scales: A, B, C, Superficial N & T

Vickers hardness testing machine

Vickers hardness as per ASTM E384

Vickers hardness as per ASTM E384

Scales: 5 HV, 10 HV, 30 HV

Scales: 5 HV, 10 HV, 30 HV

Impact testing machine

Charpy & Impact Tests on Metallic materials at ambient temperature and sub-zero temperatures -40°C & -196°C. as per ASTM E23

Charpy & Impact Tests on Metallic materials at ambient temperature and sub-zero temperatures -40°C & -196°C. as per ASTM E23

Test Range: Charpy test 0 to 300 Joules & Izod test 0 to 168 Joules

Test Range: Charpy test 0 to 300 Joules & Izod test 0 to 168 Joules

Metallurgical Tests:

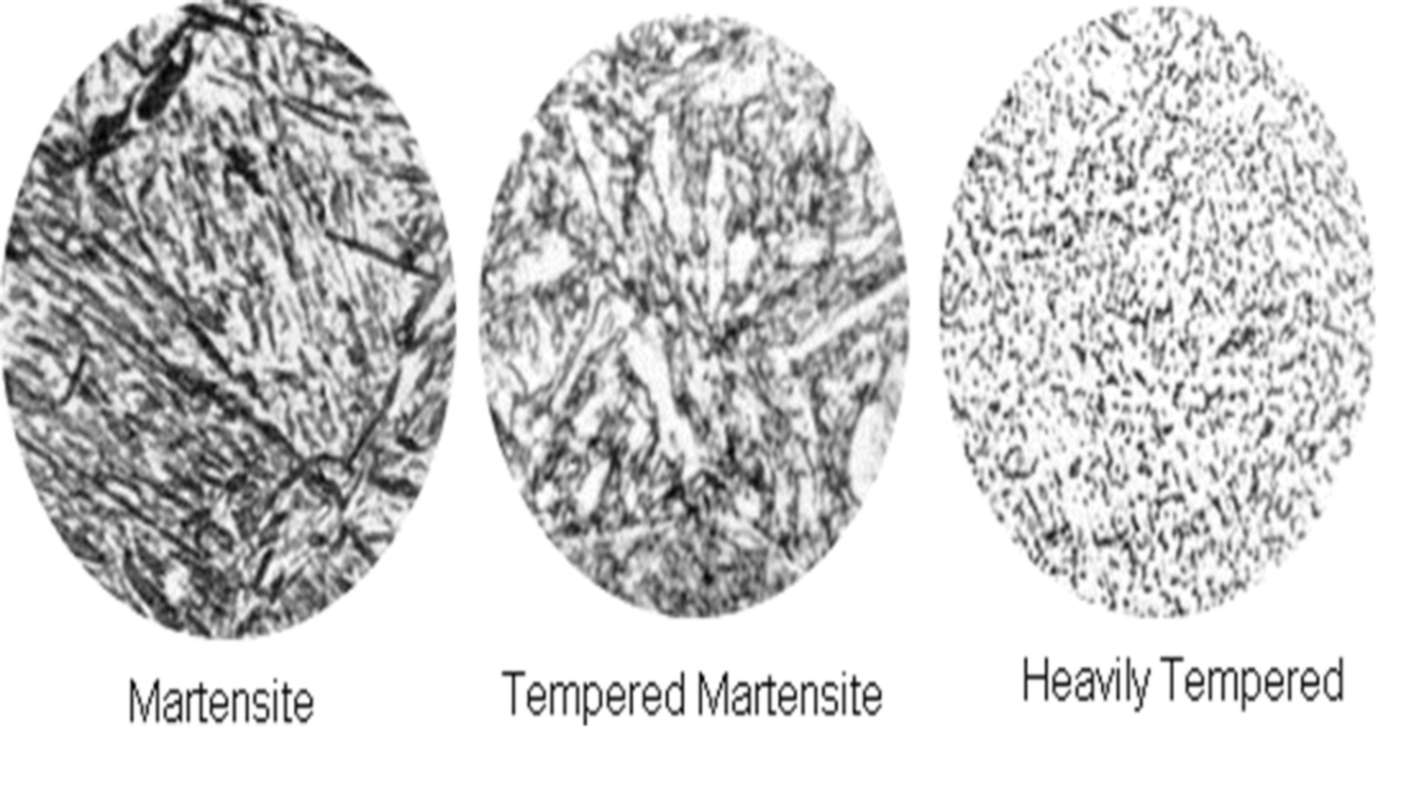

Micro Structure Evaluation

Micro Structure Evaluation

Macro Examination

Macro Examination

Heat Treat Condition

Heat Treat Condition

Decarburizing Testing

Decarburizing Testing

Weldment Evaluation

Weldment Evaluation

Weld Qualification

Weld Qualification