Production Testing & Verification

Malabou – delivering certainty through inspection, testing, and metrology.

At Malabou, we provide comprehensive inspection, testing, and metrology services to ensurethat components meet design specifications.

Our experienced metallurgists and engineers deliver inspection and testing programstailored to each client’s specification — from routine verification to fully documented, end-to-end traceability.

Core Capabilities

Chemical Analysis

Spectrographic Optical Emission analysis for ferrous and non-ferrous alloys, supported by carbon-sulphur testing for cast irons. All calibrations are traceable to Certified Reference Materials (CRMs).

AV mounts are specifically designed to isolate and reduce vibration transmission, and their primary function is to dampen vibrations to prevent wear and tear, reduce noise, and improve the longevity and performance of machinery.

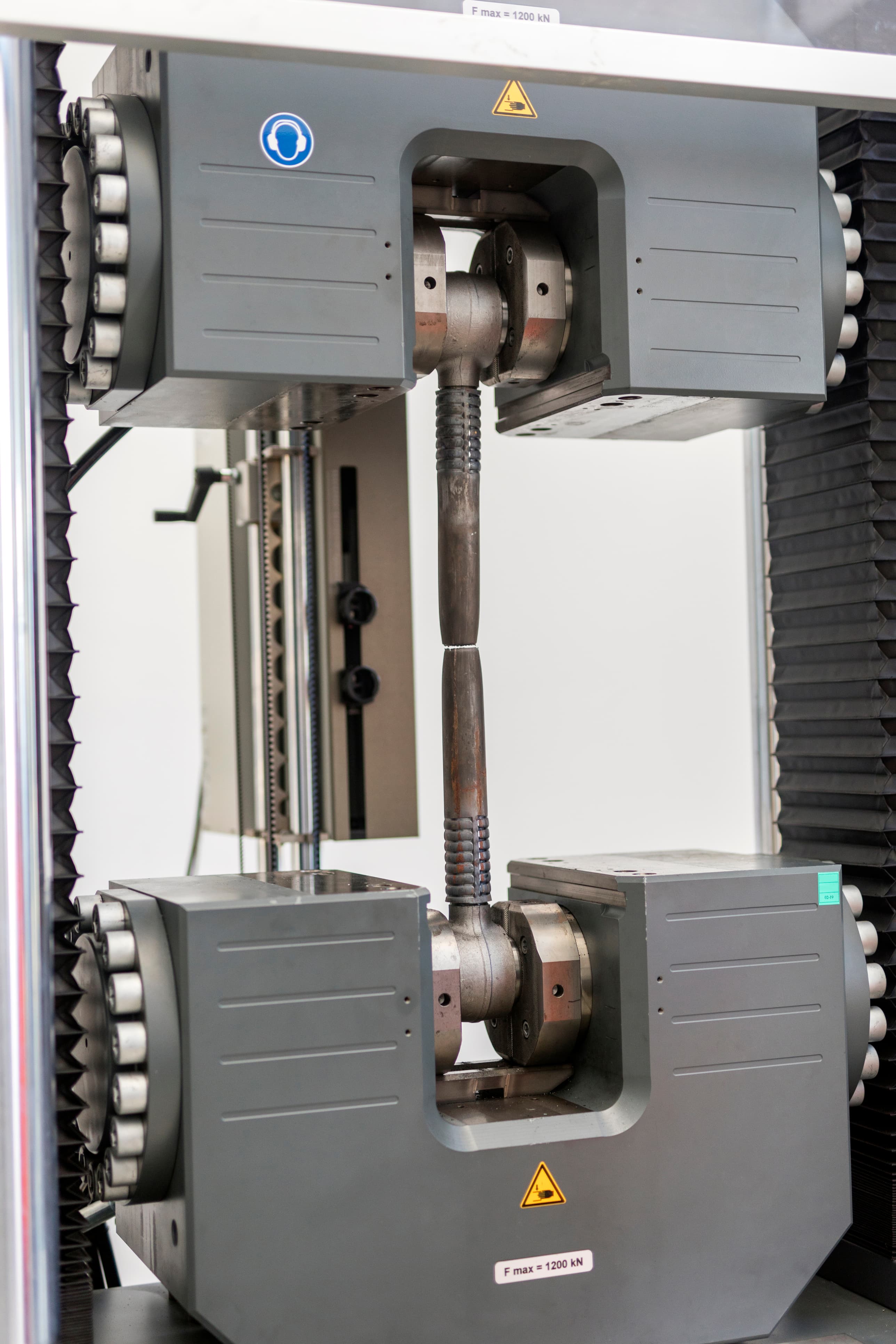

Mechanical Testing

Comprehensive mechanical testing conducted in accordance with ASTM and ISO standards,including:

Typical tests include:

Tensile, bend, and compression testing

Tensile, bend, and compression testing

Hardness testing (Brinell, Rockwell, Vickers) across a wide range of scales

Hardness testing (Brinell, Rockwell, Vickers) across a wide range of scales

Impact testing (Charpy and Izod) at ambient and sub-zero temperatures

Impact testing (Charpy and Izod) at ambient and sub-zero temperatures

Mechanical Testing

Precision GD&T verification using advanced Coordinate Measuring Machines (CMM) toassess geometry and tolerances against 3D design models accurately.

Metallurgical & Metallographic Evaluation

Detailed analysis of material structure and performance, including:

Macro and microstructure examination

Macro and microstructure examination

Weld and heat treatment evaluations

Weld and heat treatment evaluations

Grain size determination and decarburisation studies

Grain size determination and decarburisation studies

Non-Destructive Examination (NDE)

Advanced non-destructive testing inspection for the detection of surface and subsurface discontinuities without damaging components.

Non-destructive tests (NDT) include:

Visual Inspection (VT)

Visual Inspection (VT)

Magnetic Particle (MT)

Magnetic Particle (MT)

Dye Penetrant (PT)

Dye Penetrant (PT)

Ultrasonic (UT)

Ultrasonic (UT)

Radiographic (RT)

Radiographic (RT)

Leak/Pressure (LT)

Leak/Pressure (LT)

Reporting, Traceability & Quality Assurance

Every testing program is supported by robust quality documentation, including:

Documentation includes:

Traceable material and heat numbers

Traceable material and heat numbers

Equipment calibration certificates

Equipment calibration certificates

Detailed test data and photographic evidence (micrographs where applicable)

Detailed test data and photographic evidence (micrographs where applicable)

Customised Quality Plans and Inspection Test Plans (ITPs) are developed for each project,ranging from routine inspection schedules to full product qualification programs.

Non-conformances, when identified, are comprehensively documented, root-cause analysed,and tracked through to closure with corrective and preventive actions recommended.