-

Reliability in Extreme Heat Cycle Applications. Castings to ASTM A1095

In demanding industrial environments, components must withstand extreme thermal and mechanical stresses without compromising performance. ASTM A1095 sets the standard for SiMo (Silicon-Molybdenum) high-temperature castings, widely used in applications where heat resistance, durability, and dimensional stability are critical.

-

Heat-Resisting Cast Ni-Cr-FE Alloys: Unlocking Performance in Demanding Environments

When equipment faces continuous high-temperature exposure—whether in kilns, furnaces, exhaust systems, or chemical process plants—the choice of material becomes critical. Not all steels are created equal. That’s where heat-resistant cast alloys, particularly those based on Nickel-Chromium-Iron (Ni-Cr-Fe) systems, can provide the decisive edge.

-

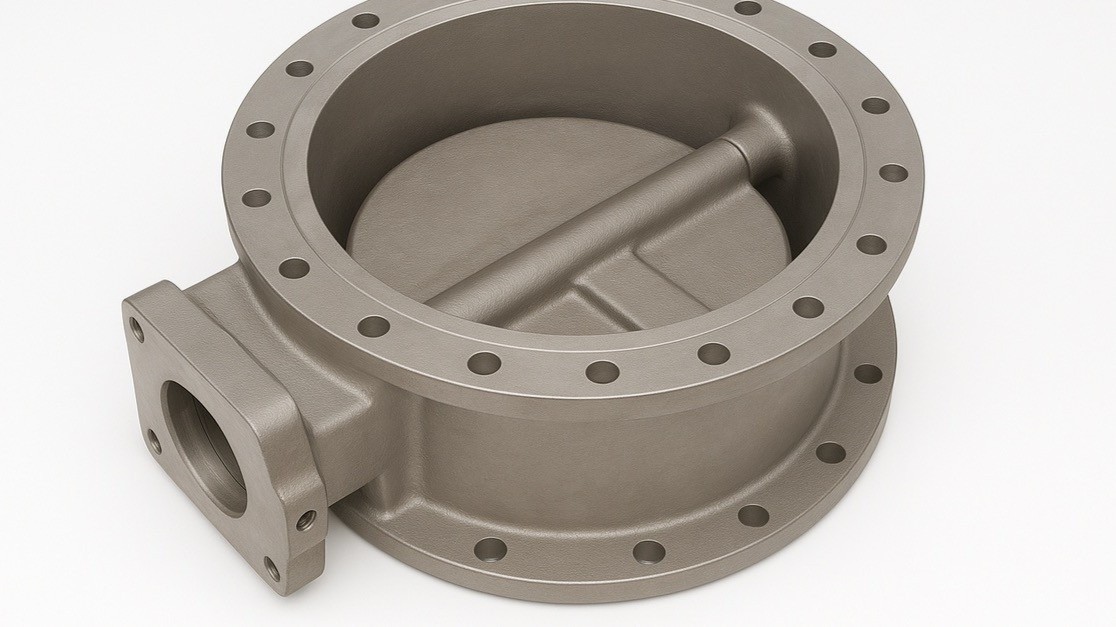

Unlocking the Benefits of Converting a Welded Fabrication into a Casting

In today’s competitive manufacturing environment, the shift from complex multi-piece weldments to monolithic castings offers compelling advantages—spanning cost-efficiency, design flexibility, material choice, weight reduction, and enhanced stiffness, especially in scalloped areas. At Malabou, we specialise in guiding OEMs through this smart transition—and here’s why it’s a game-changer

-

Cast Duplex and Super Duplex Stainless Steel – High-Performance Solutions for Demanding Environments

In industries where corrosion resistance, strength, and durability are mission-critical, few materials perform as well as duplex and super duplex stainless steels. At Malabou, we supply precision-cast duplex and super duplex components that meet the highest quality standards.

-

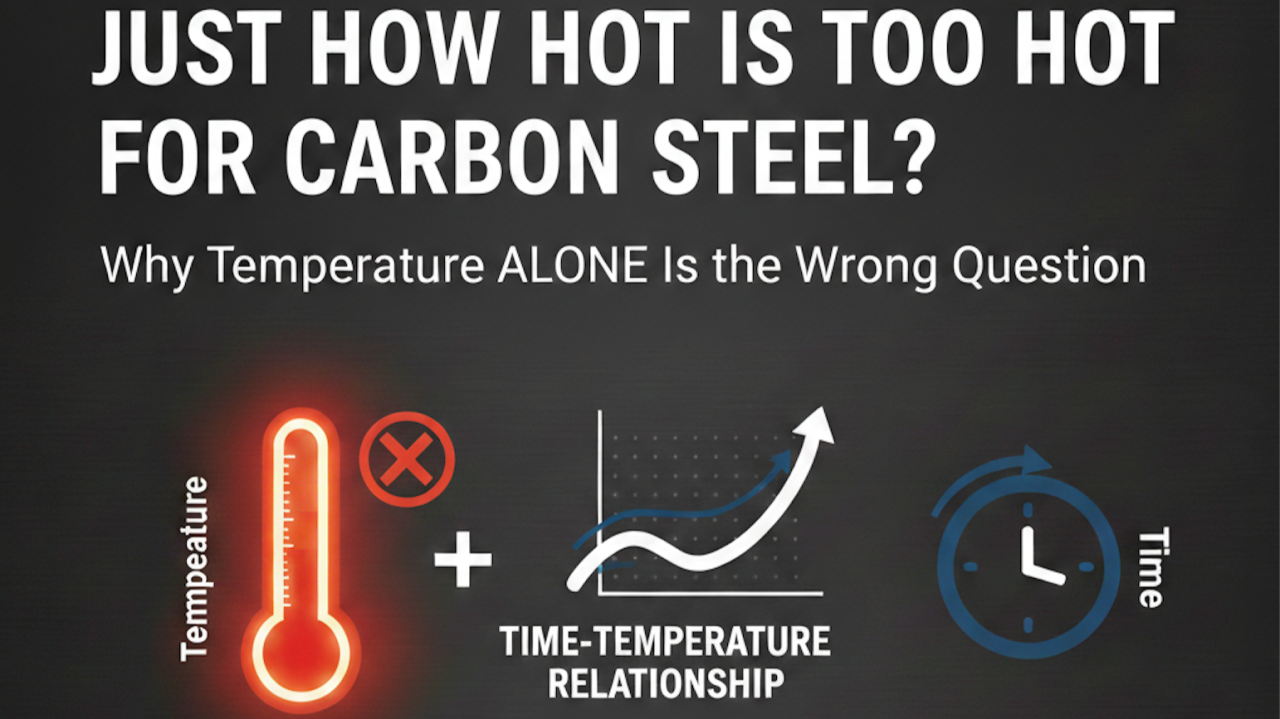

Alloy Selection for Elevated Temperature Applications: Meeting the Challenge

Understanding the metallurgy behind elevated temperature performance is essential for engineers and designers. At elevated temperature, metals don’t behave like they do at room temperature — creep, oxidation, and microstructural changes become dominant, and these must all be accounted for in design and material selection.

-

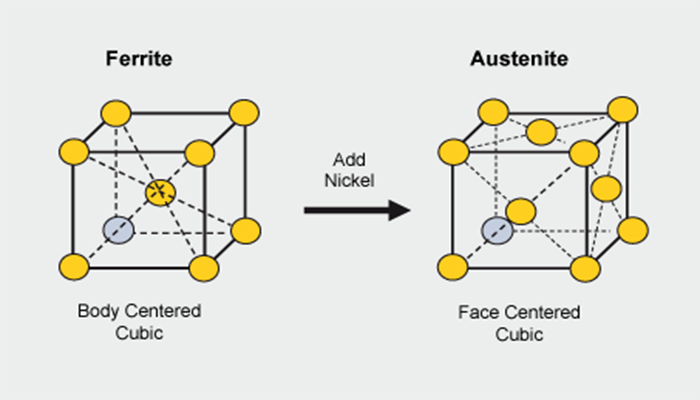

The Alternative Austenitic Stainless Steels: 200-Series Stainless Steel

The 200-series stainless steels have an unusual history. Born out of necessity during World War II, they were designed to conserve nickel—a critical alloying element in the familiar 300-series (non-magnetic) stainless steels such as 304 and 316.

-

Why a Competitive Supply Chain is a Game Changer for Local OEMs

In today’s globally competitive market, Original Equipment Manufacturers (OEMs) can’t stay ahead without a supply chain that gives them an edge. A well-optimised supply chain is no longer just about cost — it’s a vital source of competitive advantage.

-

Malabou Capabilities: Precision Metal Casting & Engineering Solutions

Malabou is a trusted provider of precision-engineered metal components, offering comprehensive solutions in metal casting, machining, fabrication, forging, and toolmaking. Serving industries across New Zealand, Australia, and globally, we specialise in delivering high-quality components tailored to your specific requirements.

-

Accelerating New Product Development with 3D-Printed Investment Casting Patterns

At Malabou, we support innovators and manufacturers by removing traditional barriers in product development. One of the most powerful ways we do this is through 3D-printed patterns for investment casting—allowing you to create functional, fully cast prototypes without committing to permanent tooling.

-

The Strategic Advantage OEMs Gain Through Optimised Metal Component Supply

Malabou partner with Original Equipment Manufacturers to achieve a competitive advantage through the outsourced supply of metal parts and components and the completion of subassemblies. As such, we are recognised as a significant contributor to OEM success and are the leading metal parts supplier in many industrial sectors.

-

A Commonwealth Tariff Advantage for Canadian OEMs and Industrial Clients

Canada applies Most Favoured Nation (MFN) tariff rates to India, meaning most industrial metal components and machinery parts enter Canada at low or zero duty — a significant advantage compared with U.S.-sourced parts exposed to changing tariff cycles.

-

Ductile Cast Iron: Delivering Reliable Components for Industrial Succes

In heavy industry, ductile cast iron is a quiet powerhouse. Its combination of strength, durability, and machinability makes it the material of choice for high-stress components — from track wheels to mining and construction machinery.

-

Engineered Castings for Severe Thermal Environments – ASTM A297 HK

ASTM A297 HK is one of the true workhorse alloys for extreme-temperature service. With excellent high-temperature strength and oxidation resistance, HK is widely specified for stressed structural components operating at temperatures up to 1150 °C (2100 °F).

-

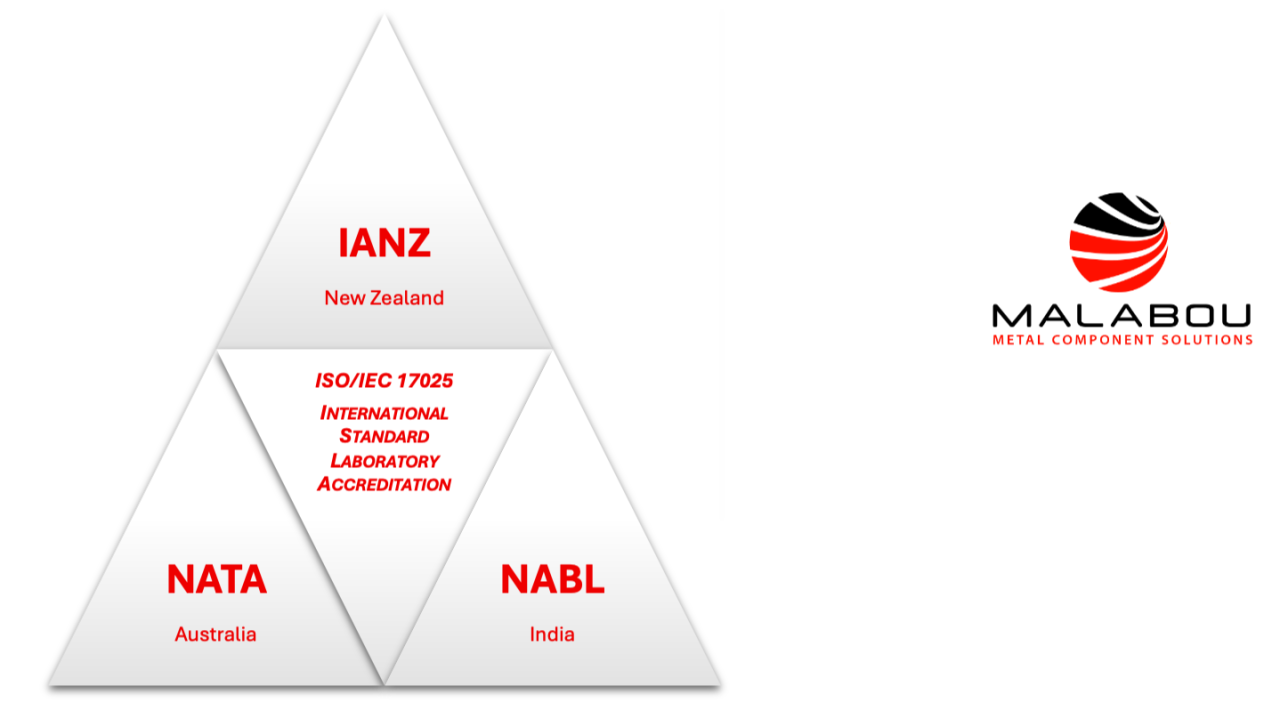

The Malabou: Verified Product Supply, Engineering Services & Independent Testing

The Malabou supports OEMs and industrial clients with verified product supply, engineering services, and independent materials testing—providing confidence that supplied components meet all specified technical requirements before entering service.

-

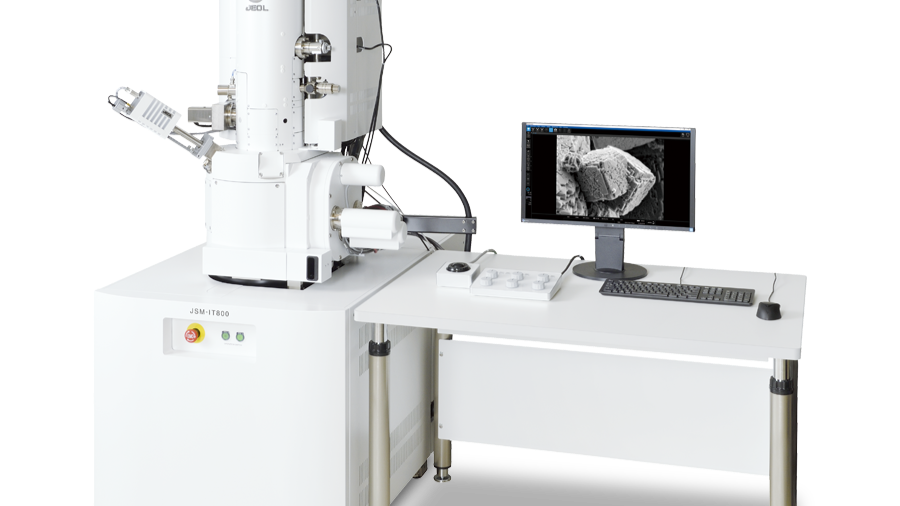

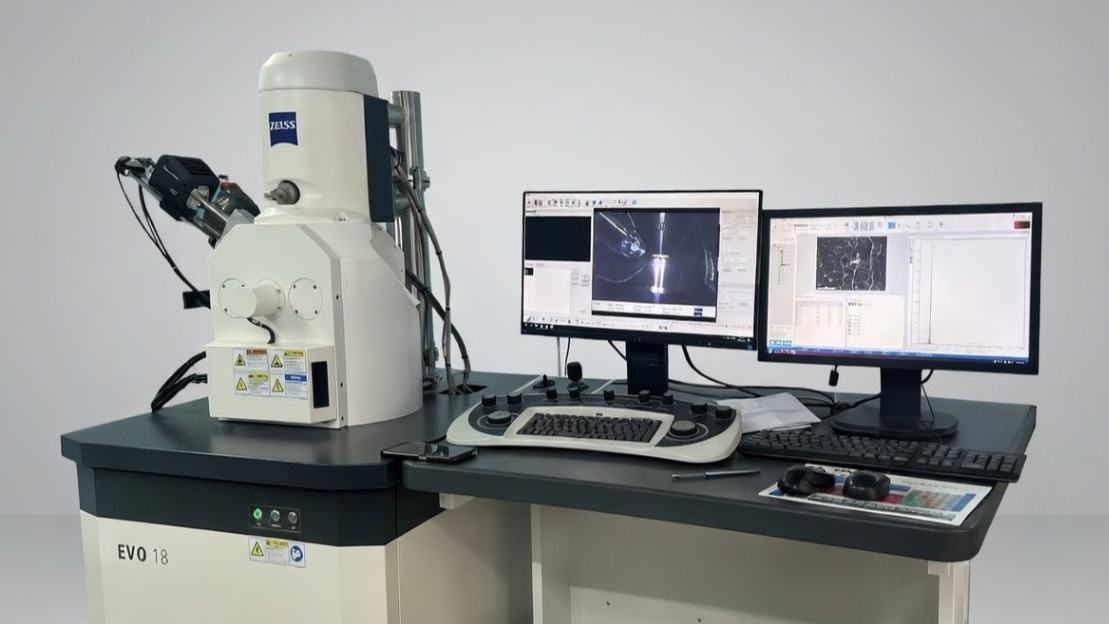

When Advanced Materials Testing Isn’t Available Locally: Managed SEM & EDX in Practice

For many OEMs, the challenge with advanced materials characterisation isn’t defining what needs to be tested — it’s accessing the right accredited capability, at the right time, without fragmenting responsibility.

-

Building Resilient Manufacturing and Supply Chains for a Complex World

A quick stopover in Singapore, on my way to India, is a reminder of what focused, long-term planning can achieve. Every visit uncovers new infrastructure, cutting-edge capabilities, and a clear intent to lead in advanced manufacturing and defence readiness.