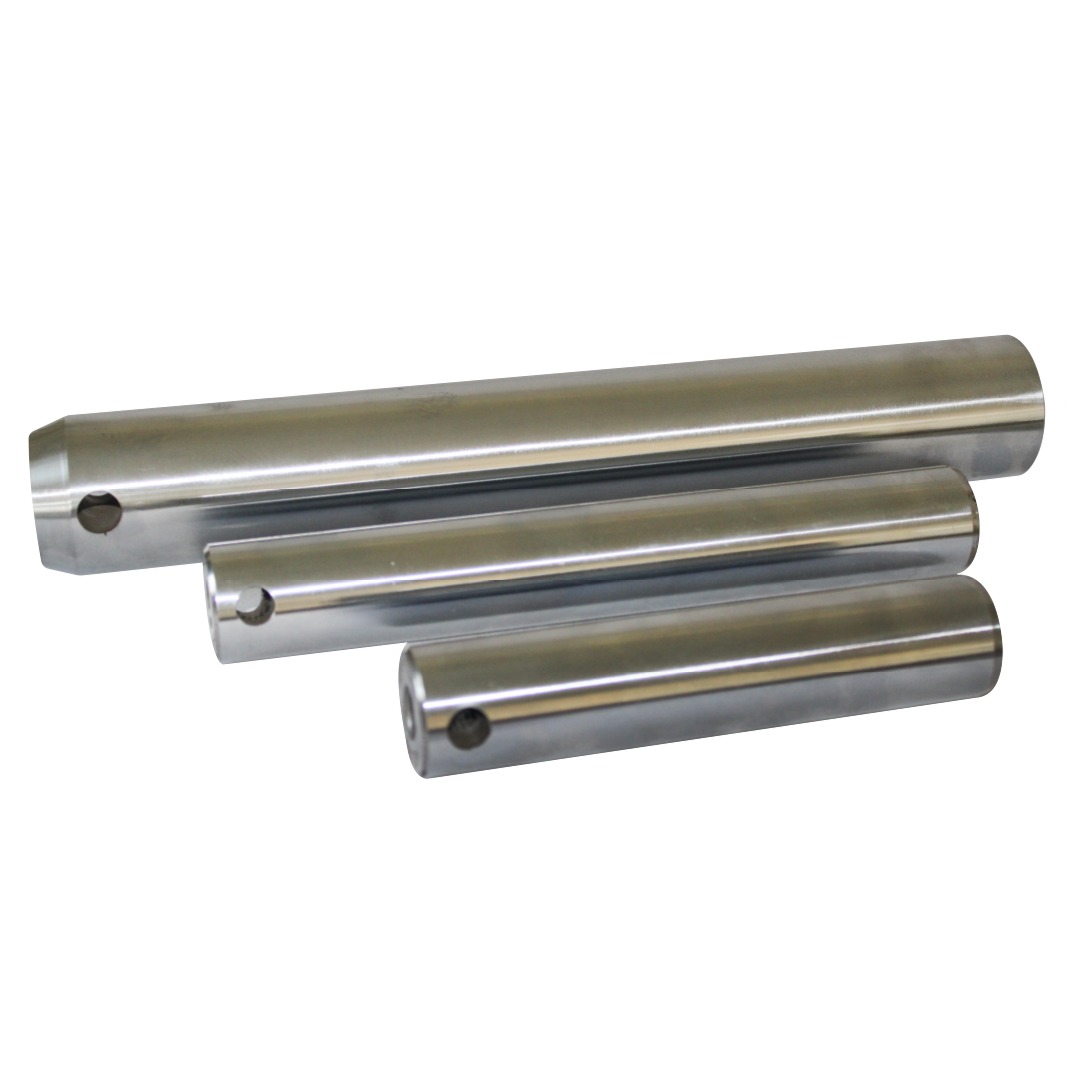

HARD CHROME BARS

HARD CHROME BARS

AISI 1045 is a Medium Carbon Steel With a Tensile Strength in the Range 600 - 800 Mpa.

It can achieve around 55 - 62 HRC surface Hardness after Induction Hardening Process and 900 - 1100 HV at the Chrome Plated Surface.

This offers Excellent Wear Resistance, Good Corrosion Resistance and High Resistance to Surface Indentation.

Typical Applications:

High strength bearings, bushings, bolts, gears, Hydraulic and pneumatic cylinders with high surface impact resistance for mining, earth moving, machine tools, waste disposal transport, car jacks, food processing, mechanical tools, hoists and compressors etc.

Standard Size: Dia 8 to 190mm.

Standard Length: Upto 3000mm.

Products

| Elemental Analysis | Base Metal |

|---|---|

| Carbon | 0.45% |

| Silicon | 0.25% |

| Manganese | 0.75% |

| Phosphorous | 0.04% |

| Sulphur | 0.04% |

| Typical Hard Chrome Plating | |

|---|---|

| Hardness | 900 - 1100 HV |

| Roughness | 0.10 - 0.30 Ra microns |

| Thickness | 15 - 30 microns |

| Typical Dimensional Tolerance | |

|---|---|

| Diameter | ISO f7 |

| Straightness | 0.2 mm / 1000 mm |

| Available Variants | ||

|---|---|---|

| S.No | Material | Manufacturing Method |

| 1 | AISI 1045 | Induction Hardened - Hard Chrome Plated Bars |

| 2 | AISI 1045 | Hard Chrome Plated Bars |

| Standard Sizes of Hard Chrome Bars | ||||||||

|---|---|---|---|---|---|---|---|---|

| Dia mm | Dia mm | Dia mm | Dia mm | Dia mm | Dia mm | Dia mm | Dia mm | Dia mm |

| 8 | 15.875/5/8" | 22.22/7/8" | 31.75/11/4" | 40 | 57.15/21/4" | 75 | 100 | 150 |

| 10 | 16 | 25 | 32 | 44.45/13/4" | 60 | 76.2/3" | 101.6/4" | 160 |

| 12 | 18 | 25.4/1" | 35 | 45 | 63 | 80 | 120 | |

| 12.7/1/2" | 19.05/3/4" | 28 | 36 | 50 | 63.5/21/2" | 85 | 125 | 180 |

| 14 | 20 | 28.56/11/8" | 38 | 50.8/2" | 65 | 90 | 130 | |

| 15 | 22 | 30 | 38.1/11/2" | 56 | 70 | 95 | 140 | 190 |

| Piston Rods & Precision Shafts | ||||||||

|---|---|---|---|---|---|---|---|---|

| Property | Specification | |||||||

| Material | EN-8 / C-45 / EN-19 / EN-24 or as per requirement | |||||||

| Standard Size | Dia 8mm to 150mm | |||||||

| Standard Length | Up to 6000mm | |||||||

| Chrome Plating Thickness | 25 to 30 microns | |||||||

| Run Out | 0.01 / 0.02mm | |||||||

| Straightness | 0.1 per meter max. | |||||||

| Surface Finish | Better than RA 0.2 | |||||||

| Chrome Surface Hardness | 850 to 1000 HV | |||||||

| Cylinder Tubes | |

|---|---|

| Property | Specification |

| Material Grade | ST 52 |

| Inner Diameter Tolerance | ISO h8, ISO h9, ISO h10 |

| Inner Diameter (ID) Surface Roughness (Ra) | ≤ 0.4 µm in Honed / Burnished Condition ≤ 0.6 µm in "AS DRAWN" Condition |

| Roundness | Within the Limits of Diameter Tolerance |

| Straightness Deviation | Max 1mm / 1000 mm |