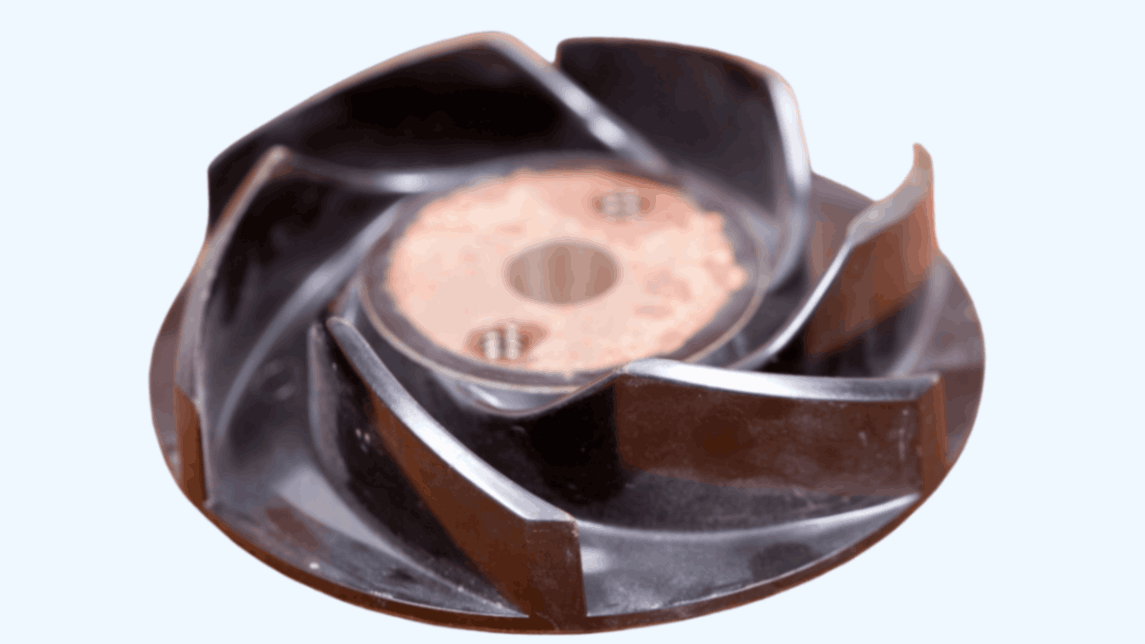

Investment Castings

Malabou can produce Investment Cast Parts of various Grades like Carbon Steel, Low Alloy Steels, Austenitic Stainless Steels, Austenitic Ferrite Duplex Steels, Super Duplex Stainless Steels, Wear Resistance grades such as HadField Manganese Steel and some Non Ferrous Grades of Copper and Bronze Alloys.

Precision Castings Made from Lost Wax Process

Investment Casting (also known as Lost Wax Casting) is a precision near net shape casting methodology.The advantages of investment casting process include:

1. Excellent surface finish

2. High dimensional accuracy

3. Complex, detailed and intricate parts can be cast

4. Wide range of metals can be cast

5. No flash or parting lines

6. Elimination or reduction of downstream operations such as machining significantly reducing total cost.

IC Tooling Design and manufacture

We design and manufacture Investment Casting tools (known as Dies) from customer supplied drawings and solid models.

We design and manufacture Investment Casting tools (known as Dies) from customer supplied drawings and solid models.

The dies are used to form the wax patterns that will form the mould cavity to cast into.

The dies are used to form the wax patterns that will form the mould cavity to cast into.

All our tooling is water cooled and CNC machined from Aluminium to give excellent surface finish and longer tool life.

All our tooling is water cooled and CNC machined from Aluminium to give excellent surface finish and longer tool life.

Major Industries Supplied

Aerospace & Marine

Aerospace & Marine

Defense

Defense

Earth Moving Industry

Earth Moving Industry

General Engineering

General Engineering

Automotive

Automotive

Forestry

Forestry

Mining Plants

Mining Plants

Valves & Pumps

Valves & Pumps

Energy & Power Plants

Energy & Power Plants

Healthcare

Healthcare